Undergraduate Study

- Clearing 2025 - limited places available!

- Undergraduate Programmes

- Undergraduate Prospectus

- Student Stories

Welcome to the School of Engineering and Materials Science

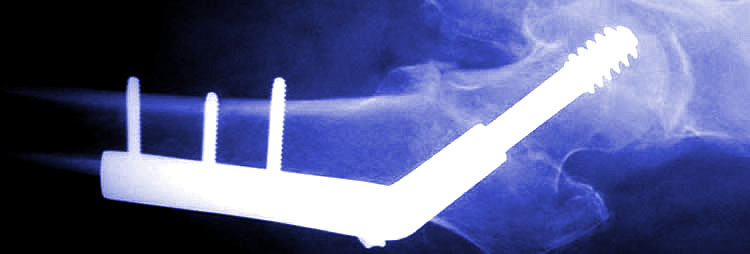

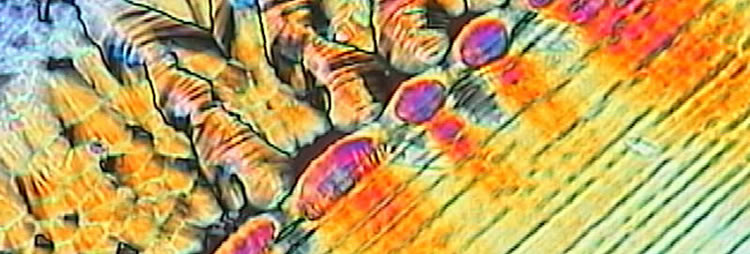

The School of Engineering and Materials Science provides outstanding degree programmes coupled with internationally leading research which is reflected in all our undergraduate programmes. Our taught postgraduate programmes are similarly first class and provide students with a fantastic opportunity to engage with cutting-edge research in: Bioengineering, Intelligent Transport, Sustainable Engineering and Engineering and Materials Education. Our extensive industrial connections provide graduates with excellent employability in stimulating and well-paid careers.

Events and Seminars

Wed 23 Jul 2025 Wed 23 Jul 202515:00 - 16:00 | Bioengineering Research Seminar: Advancing cell and gene therapy via microfluidics - Prof Aram Chung, Korea University |

Recent publications

- Tunable and anomalous electrocaloric behaviors in Bi0.5Na0.5TiO3-based relaxor enabled by dynamics of polar nanoregions

Li F, Wang X, Long M, Tan DQ, Shan L, Wang C and Yan H

Acta Materialia, Elsevier vol. 293

01-07-2025 - Effect of boron nitride on the pyroresistive properties of smart conductive polymer composites: eliminating the negative temperature coefficient effect

Wang Y, Das B, Thorn TDS, Liu Y, Papageorgiou DG, Bilotti E and Zhang H

Composites Science and Technology, Elsevier vol. 267

01-07-2025 - Stochastic reconstruction of multiphase composite microstructures using statistics-encoded neural network for poro/micro-mechanical modelling

Fu J and Tan W

Computer Methods in Applied Mechanics and Engineering, Elsevier vol. 441

01-06-2025