News

Collaboration on computational additive manufacturing published in Nature Communications

2 December 2023

The study, conducted by Dr Chinnapat Panwisawas (corresponding author) at QMUL School of Engineering and Materials Science, in collaboration with Shanghai Jiao Tong University, Centre of Excellence for Advanced Materials, and University of Leicester, has been published in the Nature Communications journal.

Laser powder-bed fusion (LPBF) offers high precision fabrication using melting-based additive manufacturing (AM), or three-dimensional (3D) printing technologies, and is globally being adopted by aerospace, automotive and even the medical industry to make commercially viable parts, disrupting the traditional manufacturing industry. Although LPBF shows great potentials in industrial application, the process can still induce defects, such as porosities, keyholes, and cracks, which extremely limit the promotion of the innovative technology.

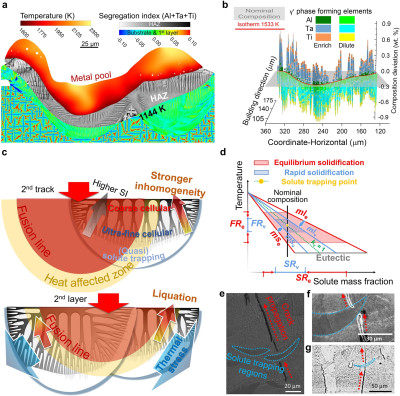

Solute element transport during rapid and repeated thermal cycle in AM which is able to induce non-equilibrium, non-uniform microstructure remains unprecedented. We have developed a computational materials engineering approach to reveal the solute transport induced by melt convection, which dilutes the partitioned solute at the solidification front, promotes solute trapping and elucidates the mechanisms of the subsequent microstructural transitions to ultra-fine cells - then to coarse cells. These suggest that the solute trapping effect could be made use of for reducing crack susceptibility by accelerating the solidification process. The detailed solidification pathway exhibits promising potential for additively manufactured ‘hard-to-print’ superalloys and aids the future materials design for better 3D printability.

Cite: N. Ren, J. Li, R.Y. Zhang, C. Panwisawas*, M. Xia, H. Dong, J. Li (2023) Solute trapping and non-equilibrium microstructure during rapid solidification of additive manufacturing. Nature Communications 14: 7990 DOI: 10.1038/s41467-023-43563-x

| Contact: | Chinnapat Panwisawas |

| Email: | c.panwisawas@qmul.ac.uk |

| Website: | |

| People: | |

| Research Centre: |

Updated by: Chinnapat Panwisawas