News

Researchers Create Multifunctional Shape-Morphing Composite Materials Inspired by Kirigami

21 August 2023

Exciting news from the collaborative efforts of researchers at Queen Mary University of London (QMUL), Nanyang Technological University (NTU) and University of Nottingham (UoN) has brought about a novel development in shape-morphing structures. Led by Dr. Wei Tan (QMUL) and Dr. Mingchao Liu (NTU, currently at University of Birmingham), the team has successfully developed an innovative method that allows materials, similar to Kirigami, to dynamically change their shapes. This achievement opens up tremendous possibilities for various applications, including soft robotics, medical devices, space structures, and aircrafts.

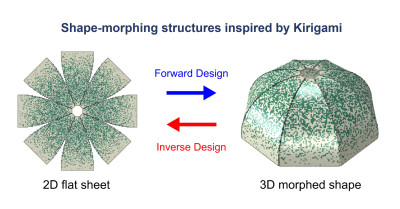

A common approach to morphing involves transitioning from a flat two-dimensional (2D) configuration to a desired three-dimensional (3D) structure. One low-cost fabrication method for achieving this is by strategically cutting a thin sheet material known as Kirigami, which, when subjected to external mechanical forces, assumes the intended 3D shape. In the past, the development of shape-morphing Kirigami structures typically involved a trial-and-error forward approach. However, the research team introduced an advanced approach by utilising mathematical equations and a material called functionally graded composites (FGCs). This method provides precise control over the bending behaviour of the material, enhancing its shape-changing capabilities.

To bring this concept to life, the researchers employed state-of-the-art 3D printing technology capable of printing different materials into "LEGO-like" blocks with varying properties, such as stiffness and flexibility, in layered structures. Through precise control over these properties, they achieved highly accurate shape transformations.

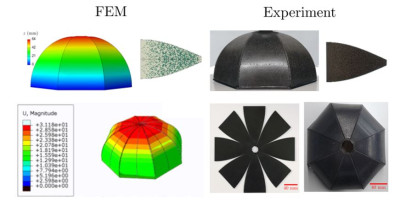

Dr Wei Tan commented “The outcomes of this research are truly remarkable. Through extensive computer simulations and real-world experiments, our team successfully produced a wide range of structures with diverse shapes and curves. These structures closely matched their intended designs, demonstrating the effectiveness of our novel approach.”

Furthermore, the team conducted comprehensive assessments of the structural strength and energy absorption capacity of the FGC-based shape-morphing structures. They performed tests on various shapes, including those resembling half an ellipse. The results obtained from computer simulations closely aligned with the experimental findings, confirming the reliability and accuracy of their research.

In addition to their shape-changing abilities, the researchers extended the materials with extra functions. Their specially engineered material exhibited the capability to combine the advantageous properties of two different materials within a single structure. For example, it demonstrated excellent heat flow while maintaining a good electrical conductivity, offering valuable applications across diverse industries.

Dr Mingchao Liu said “This new development unlocks a realm of extraordinary possibilities. With this method, researchers can create shape-changing structures using specially engineered materials. These structures hold great potential for a wide range of scenarios, even in environments with varying physical conditions.”

The lead author of the research paper, Hirak Kansara, a dedicated PhD student from QMUL, and the significant contributions of Dr. Yinfeng He from the University of Nottingham, highlight the collaborative efforts between these esteemed institutions. Their commitment to advancing knowledge and fostering innovation in the field of shape-morphing structures is evident. The work has been published in the prestigious Journal of Physics and Mechanics of Solids, further solidifying its significance in the mechanics and materials community.

Reference: Kansara, H., Liu, M., He, Y. and Tan, W., 2023. Inverse design and additive manufacturing of shape-morphing structures based on functionally graded composites. Journal of the Mechanics and Physics of Solids, p.105382.

| Contact: | Wei Tan |

| Email: | wei.tan@qmul.ac.uk |

| Website: | |

| People: | |

| Research Centres: |

Updated by: Wei Tan